Who We Are

We offer a wide range of Blow Molded Products, Injection Molded, Extrusion Blow Molding Machines, Plastic Blow Molding Products and Stretch Blow Molding Products for the Pharmaceutical, Health Care, Personal Care, Beauty, Food, Beverage, Transportation Business and Household Products Markets. When you work with Plastix, you get comprehensive technical support starting with pre-sales consultations, through to the training and service needed to make your machine work profitably.

Our Services

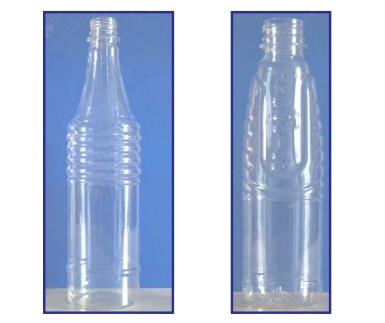

Pet Blow Molding Product

Blow molding process can be controlled by controlling various parameters such as Temperature, Pressure, Stretch time, Stretch rate, Reheat time, Cooling time, clamping pressure and relations between these parameters

Extrusion Blow Molding

In Extrusion Blow Molding (EBM), plastic is melted and extruded into a hollow tube (a parison). This parison is then captured by closing it into a cooled metal mold. Air is then blown into the parison, inflating it into the shape of the hollow bottle, container, or part.

Injection Molding Product

The injection molding machine is based on an extruder barrel and screw assembly which melts the polymer. The molten polymer is fed into a manifold where it is injected through nozzles into a hollow, heated perform mould.

Our Products

PET & Injection

Injection Blow Molding

Pet Blow Molding

Pet Blow

Molding

800 Ml

1.5lt

Pet Blow Molding

500ml

240ml

120ml

Our Mission

Our overall mission is to set the standard for quality in the Molding Industry throughout the Pakistan while maintaining the highest standards in the areas of:

- Customer satisfaction

- Cost

- Employment

- Ethical conduct

We believe this mission can best be accomplished by recognizing and meeting our fundamental responsibilities to our customers, company members, suppliers, and community allies.

Our Vision

Our vision includes expanding our company into new markets by becoming a low-cost, high-value provider of quality products. We aim to reduce time-to-market relative to the competition. Through the use of key business markers, we work toward reaching 100% quality and 100% on-time delivery to develop satisfied customers with which we can grow.